JK fermafloor is een hoogwaardig totaalsysteem samengesteld door…

Wat zijn de grote voordelen?

Download onze brochure.

- Lichtgewicht t.o.v. natbouw

- Beperkte opbouwhoogte

- Brandwerend 30-60 min

- Akoestische prestatie 12 dBa

Wat kan JK fermafloor voor mijn project betekenen?

fermacell en JK vloerverwarming slaan de handen ineen

JK fermafloor is een compleet, lichtgewicht, maatwerk droogbouw vloersysteem met een unieke samenwerking tussen twee bedrijven: fermacell BV en JK vloerverwarming. De twee bedrijven zijn uitstekend op elkaar ingesteld, waardoor de klant van begin tot eind vrij van zorgen is. Dat maakt deze samenwerking zo uniek.

Fermacell BV is verantwoordelijk voor het vloersysteem bestaande uit duurzame gipsvezelplaten (met brandwerende en akoestische eigenschappen). Het systeem wordt door JK vloerverwarming voorzien van een ingeslepen vloerverwarming compleet met de innovatieve inverse PE-RT vloerverwarmingsbuizen en hoogwaardige RVS verdeler met de benodigde appendages. Fermacell levert de specifiek voor het systeem ontwikkelde additieven, in de vorm van de JK dichtzetmassa, de benodigde JK fermafloor primer en JK fermafloor mortel die specifiek volgens het fermacell Garantsysteem gebruikt kunnen worden. Daarnaast zorgen zij voor advies en de producten t.b.v. de verdere vloerafwerking die ook weer binnen de systeemgarantie vallen.

De montage van de fermacell vloerelementen gebeurt door de speciaal geselecteerde vakmensen in afbouw. Deze experts zijn ook getraind door JK en fermacell met betrekking tot alle details van deze droogbouwvloer en kunnen de offerte voor de realisatie van het traject voor de JK fermafloor verzorgen. Zo wordt alles verzorgd vanuit één contactpersoon, van offerte tot realisatie met kwaliteitsborging en systeemgarantie. Het installeren van de complete vloerverwarming en het dichtzetten van de vloerverwarmingsbuizen gebeurt door de vakmensen van JK vloerverwarming.

- Lichtgewicht t.o.v. natbouw

- Beperkte opbouwhoogte

- Geluidsreducerend

- Brandwerend (30-60 min)

- Flexibel op maat gemaakt

- Snel in aanleg/uitvoering

- Gebaseerd op onderzoek en jarenlange ervaring

- Garantie

- Duurzaam

Referenties

Een aantal referenties van JK fermafloor...

De totaaloplossing voor o.a. architecten, uitvoerders en projectleiders

De keuze voor droge systemen in plaats van natte systemen wordt vaak gebaseerd op droogtijden, vochtbelasting van het pand tijdens de bouwfase en totale gewicht. Droogbouw houdt in dat er geen natte producten zoals zandcement, beton, anhydriet etc. worden gebruikt, waardoor de droogtijden worden geëlimineerd. Ook is droogbouw beter bestand tegen vochtbelasting en is er bij droogbouw vaak sprake van minder gewicht. Zo blijken de droge bouwsystemen, door alleen onderling bevestigen van elementen op de bouwplaats, ook nog eens tot minder bouwfouten te leiden en zijn eventuele voorkomende akoestische lekken vaak kleiner.

Het JK fermafloor droogbouwsysteem zorgt voor een onderbouwde, praktische totaaloplossing in duurzame transformatie en renovatie bouwprojecten, waarbij gewicht, geluidseisen, brandwerendheid en thermisch comfort vereisten zijn voor een juist droogbouwsysteem. De fermacell Vloerelementen zorgen ervoor dat de JK fermafloor opbouw licht van gewicht is. Daarnaast is de brandwerendheid vastgesteld conform de Europese brandclassificatie van bouwelementen met testrapport NP-1204/A/2005.

In het vloersysteem wordt de kennis en ervaring van de twee bedrijven op unieke wijze samengebracht in een totaal maatwerk, thermisch geactiveerd droogbouwvloersysteem, waarbij er bij het toepassen van het systeem per discipline een advies wordt gegeven (in de vorm van een rapportage) op de van toepassing zijnde aspecten zoals brandwerendheid, geluid, warmtestroom en een zorgeloos esthetische vloerafwerking.

Het inslijpen en leggen van de vloerverwarmingsbuizen gebeurt door de monteurs van JK vloerverwarming. De realisatie van het gehele vloersysteem wordt verzorgd door geselecteerde afbouwbedrijven met ruime ervaring met het systeem.

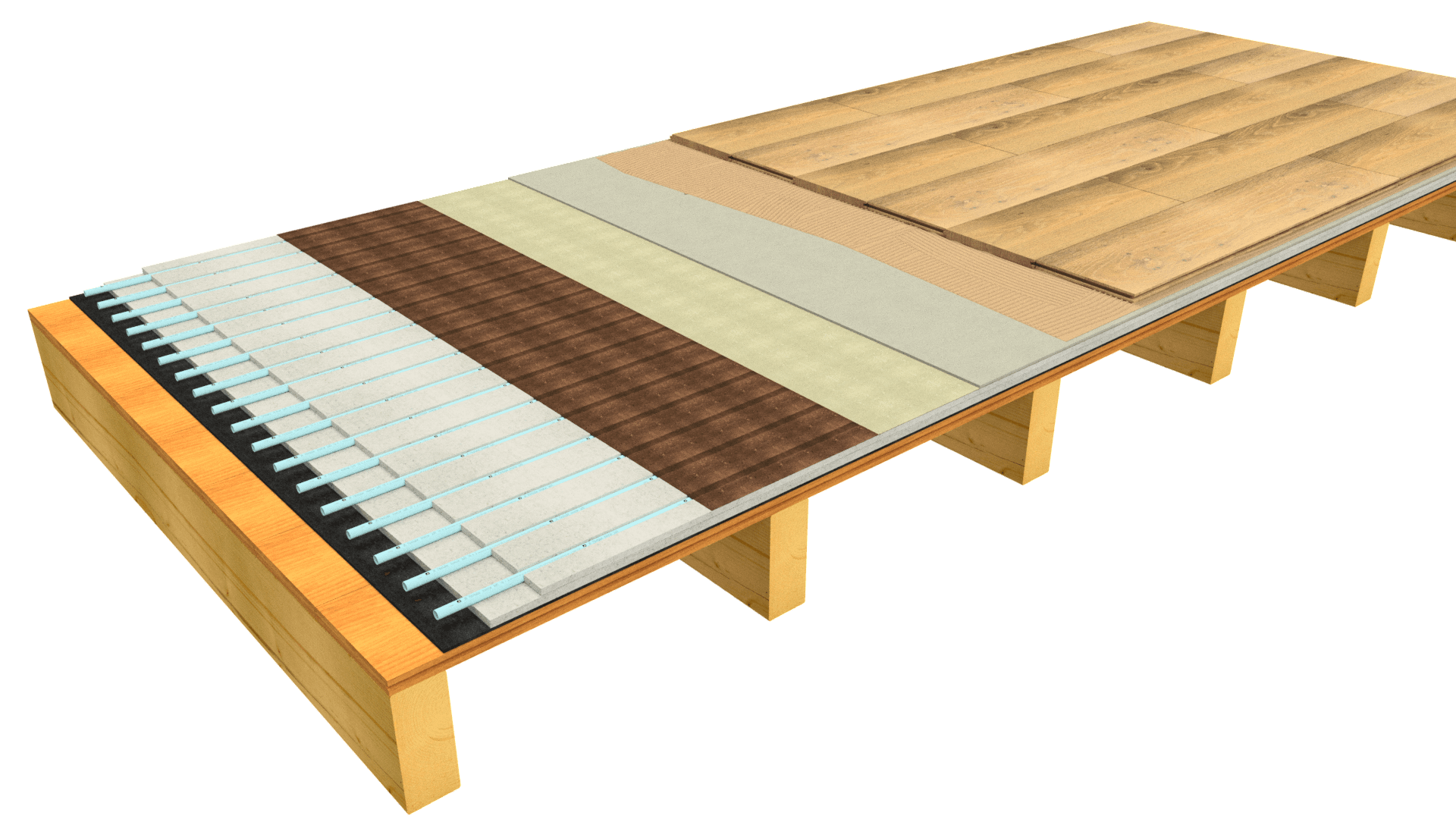

Hoe zit het JK fermafloor systeem in elkaar?

Vloerverwarming op een bouwkundig draagkrachtige, constructieve ondervloer

De opbouw van het JK fermafloor droogbouwsysteem bestaat uit twee gipsvezelplaten van fermacell van ieder 12,5 [mm] met hieronder een viltlaag van 9 [mm] voor de akoestiek (geluidsoverdracht), met de naam fermacell Vloerelement 2E26.

In deze vloerelementen wordt door JK vloerverwarming ingeslepen middels de JK ‘floorgrinder’, een gepatenteerde inslijpmachine die door JK zelf is ontwikkeld. In deze sleuven komen de JK flextube Inverse Soft vloerverwarmingsbuizen. Daarna worden de buizen dichtgezet middels optie A of optie B, gebaseerd op producten en advies van fermacell.

Meer uitleg over de twee opties is te vinden op de pagina ‘JK fermafloor’.

Bekijk onze introductie video en ervaar JK fermafloor

Experience Center

Uitgebreide scholings- en trainingsmogelijkheden

Het Experience Center biedt de unieke mogelijkheid om alle vormen van afgiftesystemen zelf te bekijken en voelen. De twee systemen van JK fermafloor zijn hier gepresenteerd met verschillende afwerkingen zoals parket, linoleum etc. Ook hier wordt de samenwerking tussen fermacell en JK vloerverwarming duidelijk, omdat er advies op maat wordt gegeven aan architecten, corporaties, verwerkers en particulieren.

- Lichtgewicht t.o.v. natbouw

- Beperkte opbouwhoogte

- Brandwerend 30-60 min

- Akoestische prestatie 12 dBa