JK fermafloor

Gebaseerd op onderzoek en jarenlange ervaring

- Lichtgewicht t.o.v. natbouw

- Beperkte opbouwhoogte

- Brandwerend 30-60 min

- Akoestische prestatie 12 dBa

Droogbouw in plaats van natbouw, waarom?

Voordelen van een droogbouw vloersysteem

Droogtijden, vochtbelasting van het pand tijdens de bouwfase, en het totale gewicht zijn overwegingen die vaak de doorslag geven om te kiezen voor een droogbouw vloersysteem. Naast deze overwegingen is een ander voordeel dat droge bouwsystemen, door alleen onderling bevestigen van elementen op de bouwplaats, vaak tot minder bouwfouten leiden. Daarnaast zijn eventuele voorkomende akoestische lekken vaak kleiner. De vloerelementen van fermacell met vilten isolatielaag komen ook nog eens tegemoet aan de toenemende vraag naar duurzame bouwmaterialen. Modern vilt bestaat voor een groot deel uit vezels van (oude) kleding, aangevuld met andere textielvezelsoorten (bijv. tapijt).

JK fermafloor is een samenwerking tussen twee partijen, waarbij twee systemen zijn ontwikkeld die met testen zijn onderbouwd. Het verwerken van de vloeren kan alleen conform de twee vrijgegeven systemen.

Voor het leggen van fermacell Vloerelementen is het noodzakelijk dat de vloerelementen volledig ondersteund worden door een draagkrachtige, constructieve vloer. De vloerelementen hebben namelijk geen vrijdragende eigenschappen. De constructieve vloer dient ook droog en vlak te zijn. Meer informatie hierover is te vinden onder downloads ‘fermacell Vloerelementen: Handleiding voor de verwerking‘.

Fermacell werkt voor de montage van de vloerelementen samen met erkende fermacell Experts, die voor u de montage kunnen verzorgen conform de richtlijnen.

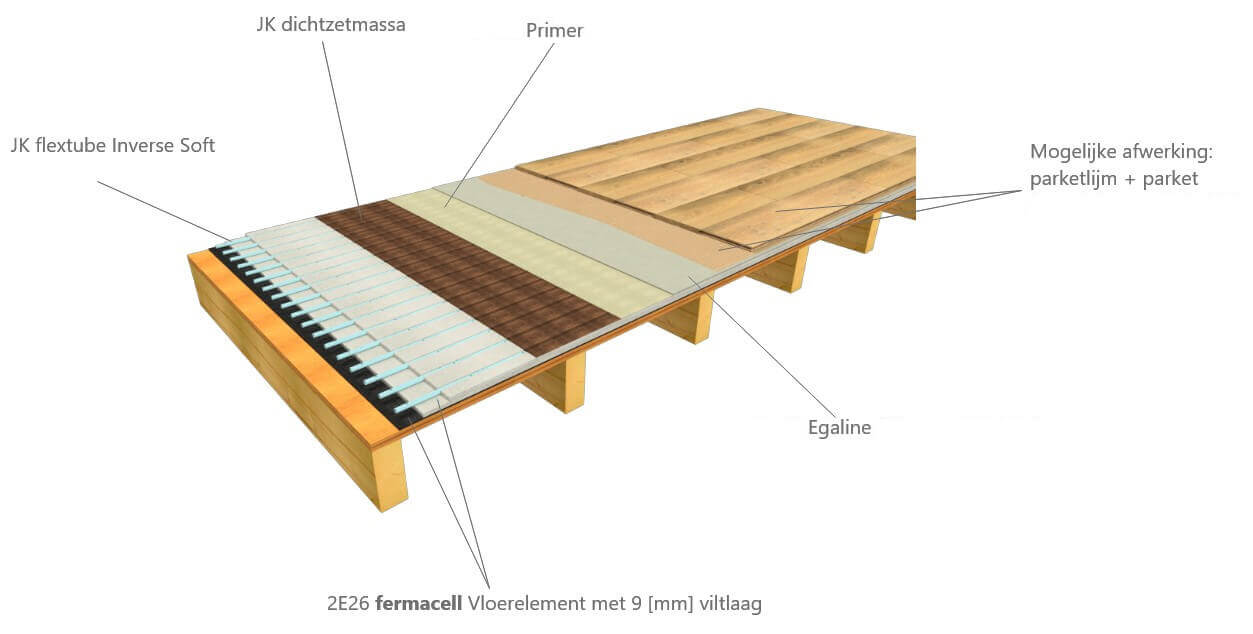

Optie A: JK dichtzetmassa

Afwerking met 2-componenten verzegelingslaag op basis van epoxyhars

De basisopbouw is voor beide opties hetzelfde. Bij de keuze voor optie A worden de ingeslepen vloerverwarmingsbuizen dichtgezet met de functionele JK dichtzetmassa, die zorgt voor het vastzetten van de buizen en een harde tussenlaag. Na deze afwerking moet het vloersysteem conform de JK fermafloor voorschriften worden afgewerkt met een door fermacell geadviseerde primer en egaline of op maat gemaakt advies. Hierna kan met de juiste vloeradditieven een van de voor JK fermafloor vrijgegeven vloerafwerkingen worden aangebracht voor een mooie esthetische vloerafwerking.

– Brandwerendheid: 30 minuten

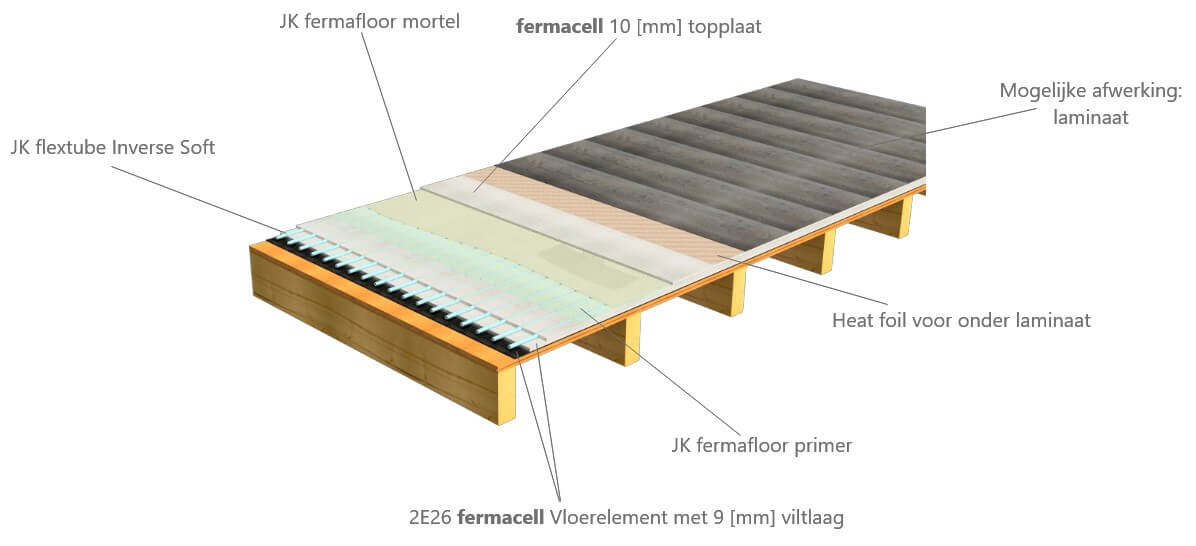

Optie B: JK fermafloor mortel met topplaat

Afwerking met een 10 [mm] drukverdeelplaat

De basisopbouw is voor beide opties hetzelfde. Wanneer gekozen wordt voor optie B wordt er na het inslijpen van de vloerverwarmingsbuizen eerst een laag JK fermafloor primer aangebracht voor de hechting. Hierna wordt met de specifiek hiervoor ontwikkelde JK fermafloor mortel de 10 [mm] topplaat van fermacell verlijmd, die tevens de vloerverwarmingsbuizen fixeert. Eventueel kan deze optie indien noodzakelijk nog worden voorzien van een fermacell egalisatielaag, geschikt voor de gipsvezelplaten. Hierna kan met de juiste vloeradditieven van fermacell een van de voor JK fermafloor vrijgegeven vloerafwerkingen worden aangebracht voor een mooie esthetische vloerafwerking.

– Brandwerendheid: 60 minuten

Gecertificeerd

Het vloersysteem is zowel bouwkundig als energetisch vastgelegd. Als afgiftesysteem heeft het geaccrediteerde onderzoekslaboratorium WTP in Berlijn de afgifte bepaald. JK is voor de ingeslepen vloerverwarming DIN Certo gecertificeerd.Op basis van een houten balklaag zonder plafond is de contactgeluidverbetering ∆ Lw van ca. 20-22 [dB] en daarmee goed toepasbaar in de verdiepingsbouw (vloerelement 2E26). Het systeem i.c.m. een verend afgehangen plafond voldoet aan de eisen van nieuwbouw. Het systeem heeft een brandwerendheid van 30-60 [min] en een minimale opbouwhoogte. Door achteraf inslijpen is het vloersysteem zeer flexibel.